How to polish the Working electrodes' surface with PK-3

PK-3 electrode polishing kit (Cat. No. 013223) is recommend for the regeneration of general working electrode surface.

The following is a guide on the different type of the working electrode polishing method using the PK-3 electrode polishing kit.

- General working electrode

- PFCE and Pyrolytic graphite electrodes

- Mesh electrode

Polishing of General Working Electrode

In the case of general polishing, polish with alumina (step No. 3 and 4) are recommended. If regeneration of the electrode surface still does not work, try the diamond polishing first.

To ensure that alumina particles adhered to the electrode surface are removed, use a new alumina polishing pad, slightly polish the washed electrode, and then rinse the electrode surface with distilled water and dry.

- Prepare the glass plate, and put a few drops of polishing diamond on a wetted diamond polishing pad.

- Hold the CV electrode at right angle to the pad, and polish in a circular motion.

- Replace the diamond pad to an alumina polishing pad, put a few drops of polishing alumina, and polish the electrode to be mirror surface. Rinse the electrode surface with distilled water, and finish by air drying.

- Using a new alumina polishing pad, polish few times the electrode (for removing the alumina particles remaining on the electrode surface). Rinse the electrode surface with distilled water, and finish by air drying.

Attention: Polishing with PK-3 is the most appropriate way to clean up electrode surface. Please consult us when other methods are applied. Please, don't use poor quality alumina, as it is not enough efficient for polishing.

Polishing of PFCE Electrode & Pyrolytic Graphite Electrode

For the electrodes listed below,

| Catalog No. | Description | Isolation | OD | ID |

| 002252 | PGBE Pyrolytic Graphite Electrode (Basal Plane) | PEEK | 6 mm | 3 mm |

| 002253 | PGEE Pyrolytic Graphite Electrode (Edge Plane) | PEEK | 6 mm | 3 mm |

| 002408 | PFCE 3 Carbon electrode | PEEK | 6 mm | 3 mm |

| 002409 | PFCE 1 Carbon electrode | PEEK | 6 mm | 1 mm |

| 011854 | SPFCE Carbon electrode | PEEK | 3 mm | 1 mm |

- Put a few drops of distilled water on the emery paper, and polish for 10 seconds. If necessary increase the polishing time.

- Then rinse the electrode with distilled water.

- After rinse, ultrasonic cleaning for 10 seconds (in the case of 65 W - 100 W ultrasonic cleaner).

Or polishing the electrode using alumina pad with a few drops of distilled water for about 10 seconds. - Then rinse the electrode again with a distilled water.

- Dry the electrode and it is ready for the measurement.

∗For the PGBE electrode (Cat. No. 002252), because of the material characteristics, it is difficult to keep the perfect basal surface. For the precise PGBE basal surface treatment evaluation, you can have the publications below as a reference.

- J. Phys. Chem.: Vol. 98 (1994), p. 5314; Vol. 96 (1992), p. 3124

- Anal. Chem.: Vol. 64 (1992), p. 2518; Vol. 61 (1989), p. 1637; Vol. 69(1997), p. 4680

The assessment of the basal and edge surface is done by measuring the Raman spectra. This method is reported in the last two publications mentioned above.

∗notice

Do not polish with a finer grade of emery paper (#6000 etc.).

PFCE electrode does not need mirror finishing like a GC electrode.

Polishing of Mesh Electrode

Mesh electrode is a small and fragile electrode, and you can not polish in an usual way.

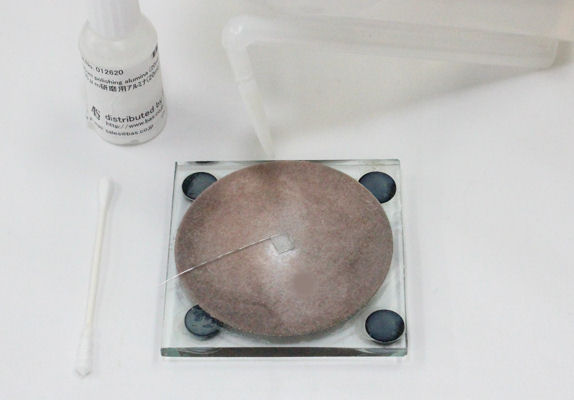

One recommended way is the regeneration of the electrode by a weakly polishing with 0.05 µm polishing alumina (Cat. No. 012620) using cotton swab, as shown bellow.

Fig. 1 Drip one or two drops of distilled water onto alumina pad, before drop the 0.05 µm polishing alumina (Cat. No. 012620).

Fig. 1 Drip one or two drops of distilled water onto alumina pad, before drop the 0.05 µm polishing alumina (Cat. No. 012620).

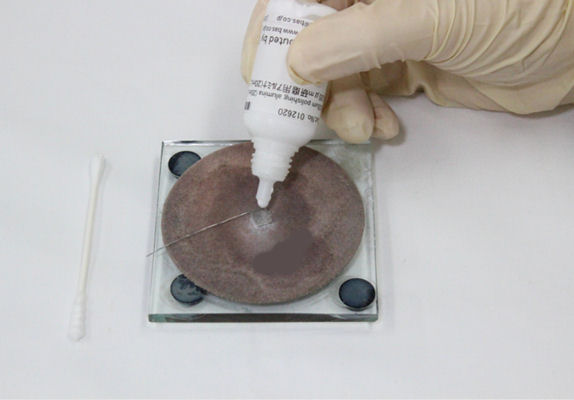

Fig. 2 Drip one or two drops of 0.05 µm polishing alumina (Cat. No. 012620) over the mesh electrode.

Fig. 2 Drip one or two drops of 0.05 µm polishing alumina (Cat. No. 012620) over the mesh electrode.

Fig. 3 Touch lightly with a cotton swab, be careful to do not to put too much force.

Fig. 3 Touch lightly with a cotton swab, be careful to do not to put too much force.Never rub, because if you do it, you will broke the electrode.

After polish with 0.05 µm polishing alumina (Cat. No. 012620), rinse with distilled water and dry.

If the residual alumina still remain in the surface of the electrode after rinse with distilled water, do the ultrasonic cleaning (65 - 100 W) for a short time (about 10 seconds), and rinse again with distilled water and dry.