10. DRE Disk replaceable electrode

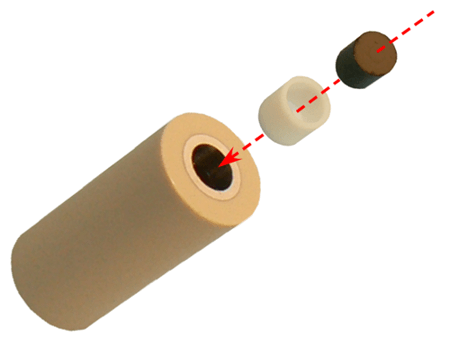

The Disk Replaceable Electrode (DRE) will have the Disk electrode removable.

The replacement of the disk electrode will be possible from both side, front side and rear side. It will make possible to choose, according to the condition required for your research purpose.

- Features

- RRDE

- RDE

- Tool kit

- Handling

- Assessment

- Technical note

- Assessment of the disk electrode using the same ring electrode, could avoid the influence of the ring material and dimension.

- Removable disk and ring assembly make possible modification of the electrode surface and polishing process, separately.

- Disposable disk could be used.

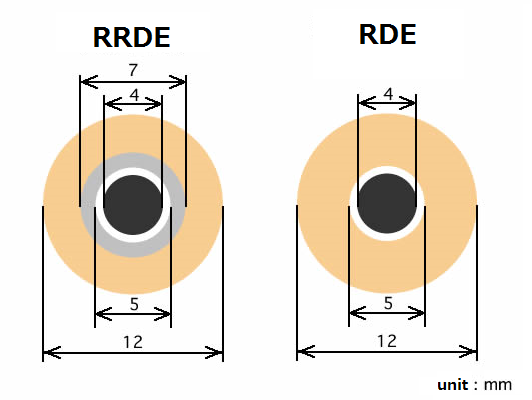

Size

The electrode length is 25 mm for the ring disk electrode (RRDE) and 26 mm for the disk electrode (RDE). (Both are reference values).

Disk Replaceable Electrode (DRE) for RRDE

DRE-PGK Pt ring/GC disk replaceable electrode kit

| Catalog No. | Description |

| 013336 | DRE-PGK Pt ring/GC disk replaceable electrode kit |

| Component | |

| 013337 | DRE-PTR Pt ring assembly |

| 013339 | DRE-SPC Teflon spacer (3 pcs) |

| 013338 | DRE-GCD GC disk |

| Optional items | |

| 013366 | DRE-AUD Au disk |

| 013367 | DRE-PTD Pt disk |

DRE-GGK GC ring/GC disk replaceable electrode kit

| Catalog No. | Description |

| 013641 | DRE-GGK GC ring/GC disk replaceable electrode kit |

| Component | |

| 013642 | DRE-GCR GC ring assembly |

| 013339 | DRE-SPC Teflon spacer (3 pcs) |

| 013338 | DRE-GCD GC disk |

| Optional items | |

| 013366 | DRE-AUD Au disk |

| 013367 | DRE-PTD Pt disk |

| Catalog No. | Description |

| 013362 | DRE-GCK GC disk replaceable electrode kit |

| 013364 | DRE-AUK Au disk replaceable electrode kit |

| 013365 | DRE-PTK Pt disk replaceable electrode kit |

| Common components | |

| 013361 | DRE-DAS Disk assembly |

| 013339 | DRE-SPC Teflon spacer (3 pcs) |

| Optional items | |

| 013338 | DRE-GCD GC disk |

| 013366 | DRE-AUD Au disk |

| 013367 | DRE-PTD Pt disk |

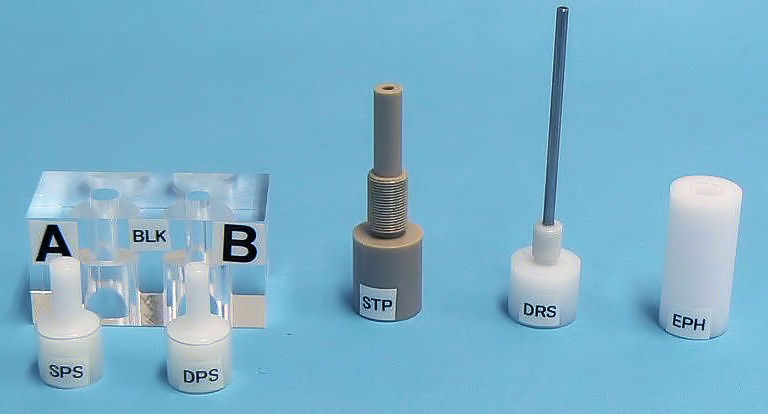

DRE-DCP - Disk electrode polishing and exchanging tool kit

| Catalog No. | Description |

| 013608 | DRE-DCP Disk electrode polishing and exchanging tool kit |

| Component | |

| - | DRE-BLK Base block |

| - | DRE-STP Stopper |

| - | DRE-DRS Disk remove tool |

| - | DRE-SPS Spacer push tool |

| - | DRE-DPS Disk push tool |

| - | DRE-EPH Electrode polishing holder |

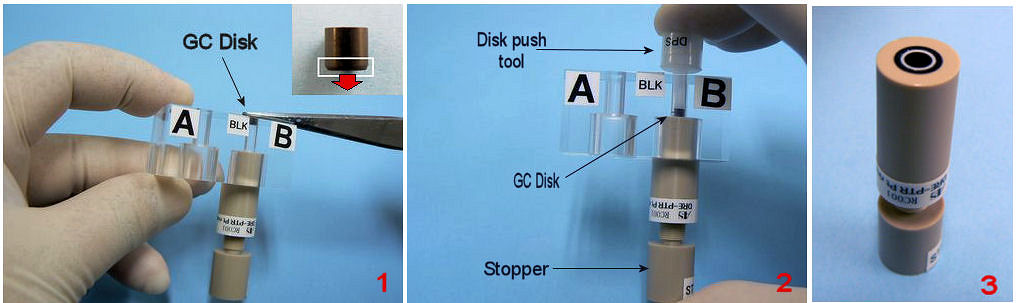

Handling sketch of the DRE

The DRE-STP Stopper is screwed to the DRE-PTR Pt ring assembly. It works for the adjustment of the height, when the DRE-SPC Teflon spacer and DRE-GCD GC disk are attached.

In the DRE-BLK Base block, the “A” side is for the DRE-SPC Teflon spacer attachment, and “B” side is for the DRE-GCD GC disk attachment.

...after fixed and adjusted the height of the DRE-SPC Teflon spacer in to the DRE-PTR Pt ring assembly, move the DRE-PTR Pt ring assembly to the “B” side.

Put the DRE-GCD GC disk from the front (Fig. 1) and adjust it with DRE-DPS Disk push tool (Fig. 2).

Take out from the DRE-BLK Base block and adjust the height with DRE-STP Stopper and DRE-DRS Disk remove tool, until have the flat surface (Fig. 3).

RRDE Disk replaceable electrode assessment test

The illustration in the section above shows the fitting of the DRE-GCD Glassy carbon disk from the front side, however for the performance test of the electrode, both way, front side and rear side was done.

Typical test parameters are:

Working electrode : DRE-RRDE Pt ring GC disk electrode

Reference electrode: Ag/AgCl

Counter electrode : Platinum wire

Test solution : 2 mM Ferricyanide/1 M KNO3

Initial voltage : + 600 mV

Final voltage : - 200 mV

Scan Rate (Volt) : 10 mV/S

Rotation Rate : 100 to 3,000 rpm

Sensitivity : 10-5 V/A

2nd potential : + 600 mV

Fitting for the front side:

Fitting for the rear side:

Technical note

How to polish the DRE-PTR Pt ring assembly?

In the package, when you received the DRE-PGK Pt ring/GC disk replaceable electrode kit, the DRE-PTR Pt ring assembly is setting in the tube, fixed with a silicon rod to do not move.

Do not throw out the silicon rod!

It will be used for the polish of the DRE-PTR Pt ring assembly.

|

|

|

| Cut the silicon rod into 0.5 cm and insert into assembly from the connect side. |

Push the silicon rod into the ring assembly by using DRE-STP slowly. Be care to keep the silicon rod surface flat or slight lower position than the Pt ring surface. Then follow the general electrode polishing procedure indicated in our website from PK-3 Electrode Polishing Kit. | After polishing, screw the DRE-STP to push out the silicon rod, removing it from the electrode side. DRE-STP must be used for removing the silicon rod. Any Pt ring damage, due to the use of other tool for the removing of the silicon rod, is out of guaranty range. |

※ RDE/RRDE/DRE electrodes are designed to be used in RRDE-3A Rotating Ring Disk Electrode Apparatus, we will not guarantee the operation when ALS RDE/RRDE/DRE electrodes are used in combination with RRDE apparatus made by other companies.